Kaiser Permanente Vacaville featuring Stucco Stops

The Kaiser Permanente Hospital in Vacaville was a four-year project that created over 340,000 square feet of medical operations. The hospital is a 4-story, 174-bed facility that is only a part of a “campus-style” medical center. Alongside of the hospital is a 219,000 square foot medical office building and a central utility plant.

Flannery provided Plaster Channel Screeds (PCS) and Expansion Reveals (EXP) for the exterior of the building. In addition to the straight trims, we also manufactured pre-fabricated intersections in order to assist in the “grid” like design of the exterior plaster finish.

More About the Trims from this Project:

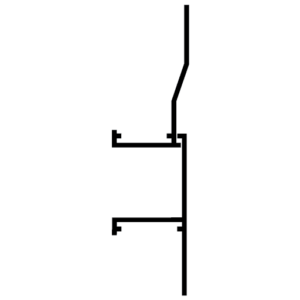

Flannery’s Plaster Channel Screeds create an aesthetic reveal in any stucco wall system. Channel Screeds break up plaster or stucco walls by creating horizontal and vertical reveal lines. Flannery’s Plaster Channel Screeds come in a number of depths for different stucco thicknesses as well as a number of reveal widths for just the right design look. Select sizes of Flannery’s Plaster Channel Screeds are also available with Aluminum Alignment Splices or Vinyl Connectors to ease the installation process and create crisp and clean butt joints and lines. If you are looking to achieve a small depth at 1/4”, take a look at our Plaster Control Joint.

Flannery’s 2-Piece Expansion Reveal acts as a plaster expansion joint designed to allow for the minor movement that may occur within an interior or exterior stucco finish. The Expansion Reveal creates an aesthetic reveal similar to the Plaster Channel Screed and allows for a ¼” of movement. Expansion movement may be increased with Flannery’s selection of custom expansion reveals and extended flanges. Select sizes of Flannery’s 2-Piece Expansion Reveals are available with Aluminum Alignment Splices to ease the installation process and create crisp and clean butt joints and lines.

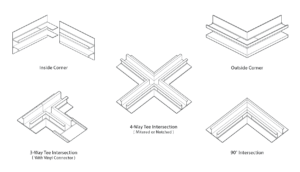

Intersections:

Flannery offers prefabricated intersections and corners for intricate building designs that utilize intersecting lines and bands on exterior walls. Prefabricated intersections and corners are mitered and then welded together at their attachment flanges, then vinyl tape is applied to the back of the reveal to prevent water intrusion. Factory welded intersections and corners come with 6” legs, however custom leg lengths can be ordered.

Flannery offers prefabricated intersections and corners for intricate building designs that utilize intersecting lines and bands on exterior walls. Prefabricated intersections and corners are mitered and then welded together at their attachment flanges, then vinyl tape is applied to the back of the reveal to prevent water intrusion. Factory welded intersections and corners come with 6” legs, however custom leg lengths can be ordered.