Composite Siding Trim

Showing all 16 results

-

Siding J-Mold

Read more -

Siding Outside Corner

Read more -

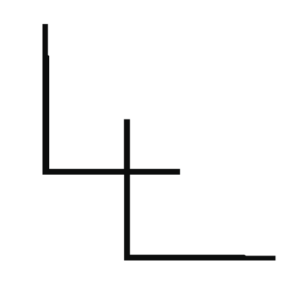

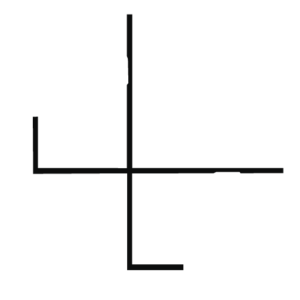

Siding X-Mold

Read more -

Siding H-Mold

Read more -

Siding Inside Corner Reveal

Read more -

Z-Fur Strip

Read more -

Furring Strip

Read more -

Starter J-Vent

Read more -

Starter J-Strip

Read more -

Aluminum Furring Strip

Read more -

Siding Flatboard Starter Strip

Read more -

Commercial Siding Starter Strip

Read more -

Siding Inside Corner for Fiberon® Cladding

Read more -

Siding X-Mold for Fiberon® Cladding

Read more -

Siding Outside Corner for Fiberon® Cladding

Read more -

Siding J-Mold for Fiberon® Cladding

Read more

Choosing the Right Siding Trim for the Project

Choosing the right composite siding trim to get the look you and your customer want is important. Each piece of trim has its own unique design and creates a different look depending on what the customer wants and needs. At Flannery Trim, we provide only the highest quality materials for our customers because we know quality is key in every area of business.

To help you choose the right siding trim for your customers’ needs, here is a brief summary of each of the options we supply for composite siding trim and their specific uses:

- Siding flatboard starter strips are used for installing the first level of TruGrain siding. Due to its “tongue and groove” process, the starter strips are needed for the first layer of siding to hook to when hanging. The starter strips will maintain a clean edge for the siding.

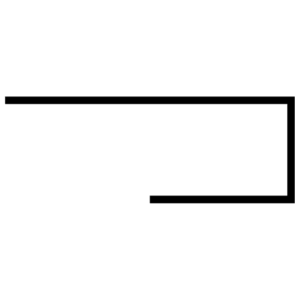

- Siding J-mold allows a nice, clean flow of siding when a dissimilar wall or material could create a rough edge with the siding.

- Siding H-mold is a siding trim that combines with two adjoining siding pieces and creates a flat look. This siding trim fits between the two pieces of siding and comes with a face flange that then allows you to slide the siding behind the flange to cover the unfinished edge of the panel.

- Siding X-mold creates a solid, clean corner reveal where it would otherwise normally be required to be mitered and laid together.

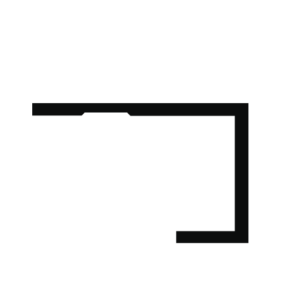

- Siding outside corner is specifically used for siding that meets at a 90° angle to create a sharp, outside corner joint.

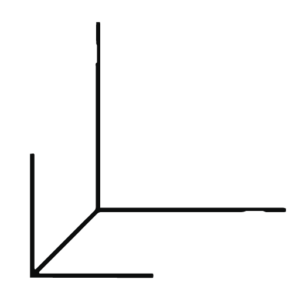

- Siding inside corner is similar to the siding outside corner except that it is used for a 90° angle at an inside corner joint.

- Aluminum furring strips allow air movement behind siding by holding composite siding away from the substrate. The aluminum material ensures the furring strips will not rust or rot.

- Commercial siding starter strips are just like the siding flatboard starter strips mentioned above but for TruGrain commercial siding.