Plaster Parapet Cap

Trim Purpose

Specs, MSDS, and LEED Information for Flannery Trims & Products

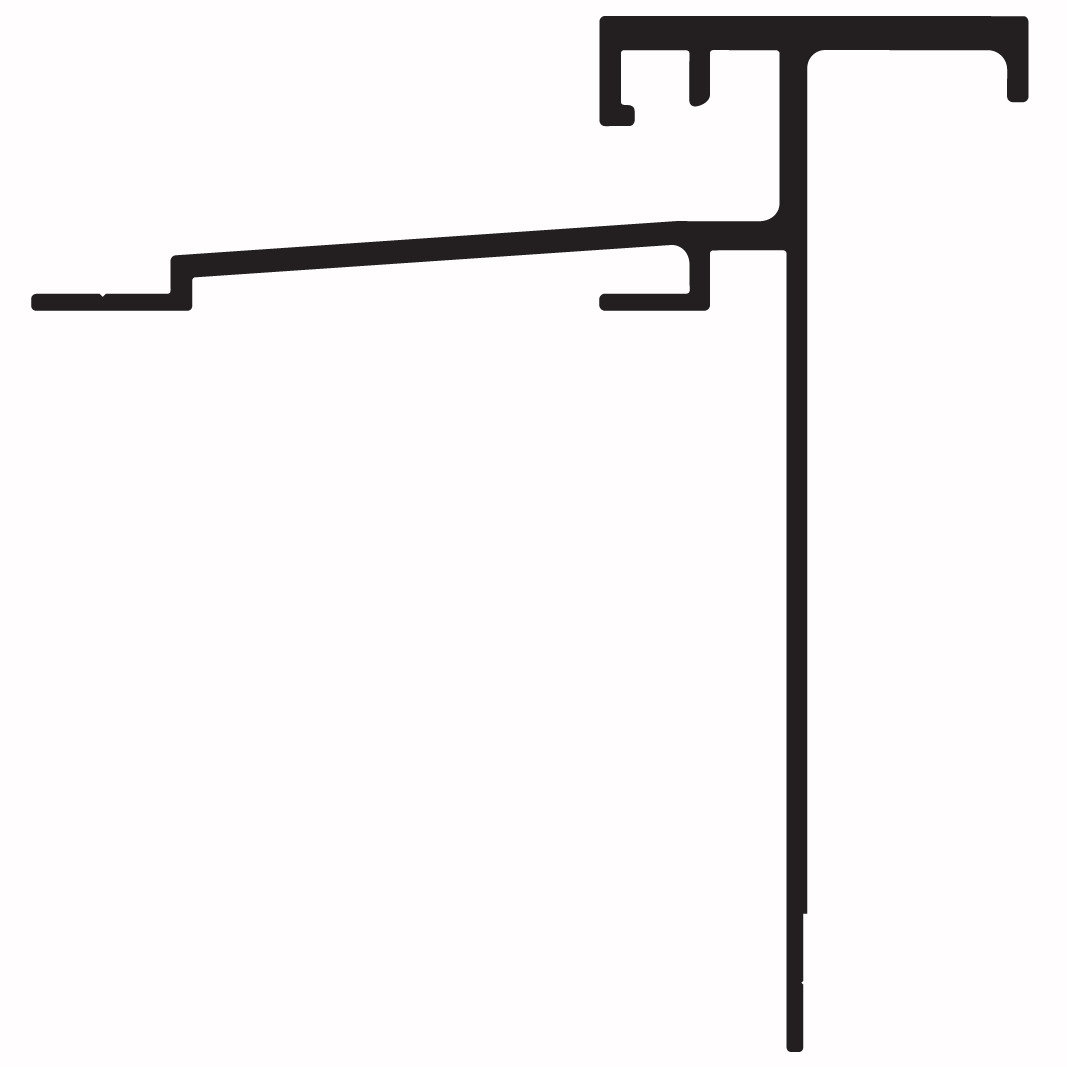

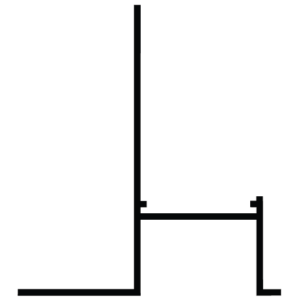

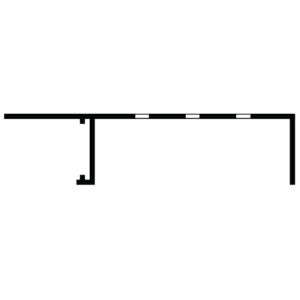

Flannery’s Plaster Parapet Cap is a stucco termination trim that is to be used at the top of exterior walls without an overhang or soffit. The Plaster Parapet Cap has a return leg that can be integrated into a fabricated sheet metal parapet cap to finish off the building’s parapet and prevent moisture from getting behind the roofing materials. Flannery can also manufacture the custom sheet metal return leg if needed to ensure the Plaster Parapet Cap functions exactly how you need it to in your building design.

Product Details

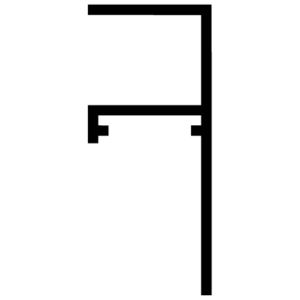

Flannery’s Aluminum Plaster Trims are standard extruded aluminum alloy 6063 T5 and have .050” nominal wall thickness. Plaster and Stucco trims come in 10′ lengths and shall have a standard Mill Finish (for field priming & painting) or a Clear Anodized Finish. Other factory finishes and custom paint orders, including Chem-film or Primer, are available. You can view our factory finishes to see if we have what you are looking for or if you do not see the finish, you are looking for, chances are we can color-match it or we already have it! Flannery Trim wants to always make sure we can get you the right look and feel for your building project.

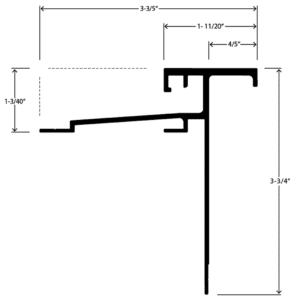

As seen above, the Plaster Parapet only comes in one size. However, the Plaster Parapet Cap has a return leg that can be integrated into a fabricated sheet metal parapet cap to finish off the building’s parapet and prevent moisture from getting behind the roofing materials. So, Flannery can also manufacture the custom sheet metal return leg if needed to ensure the Plaster Parapet Cap functions exactly how you need it to in your building design. Flannery wants to ensure their customers will always be satisfied with all of our parts and that is why we are always open to customizations need be.

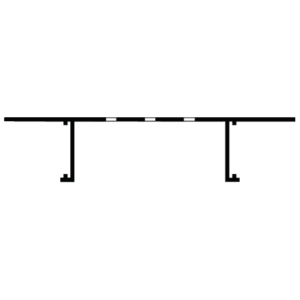

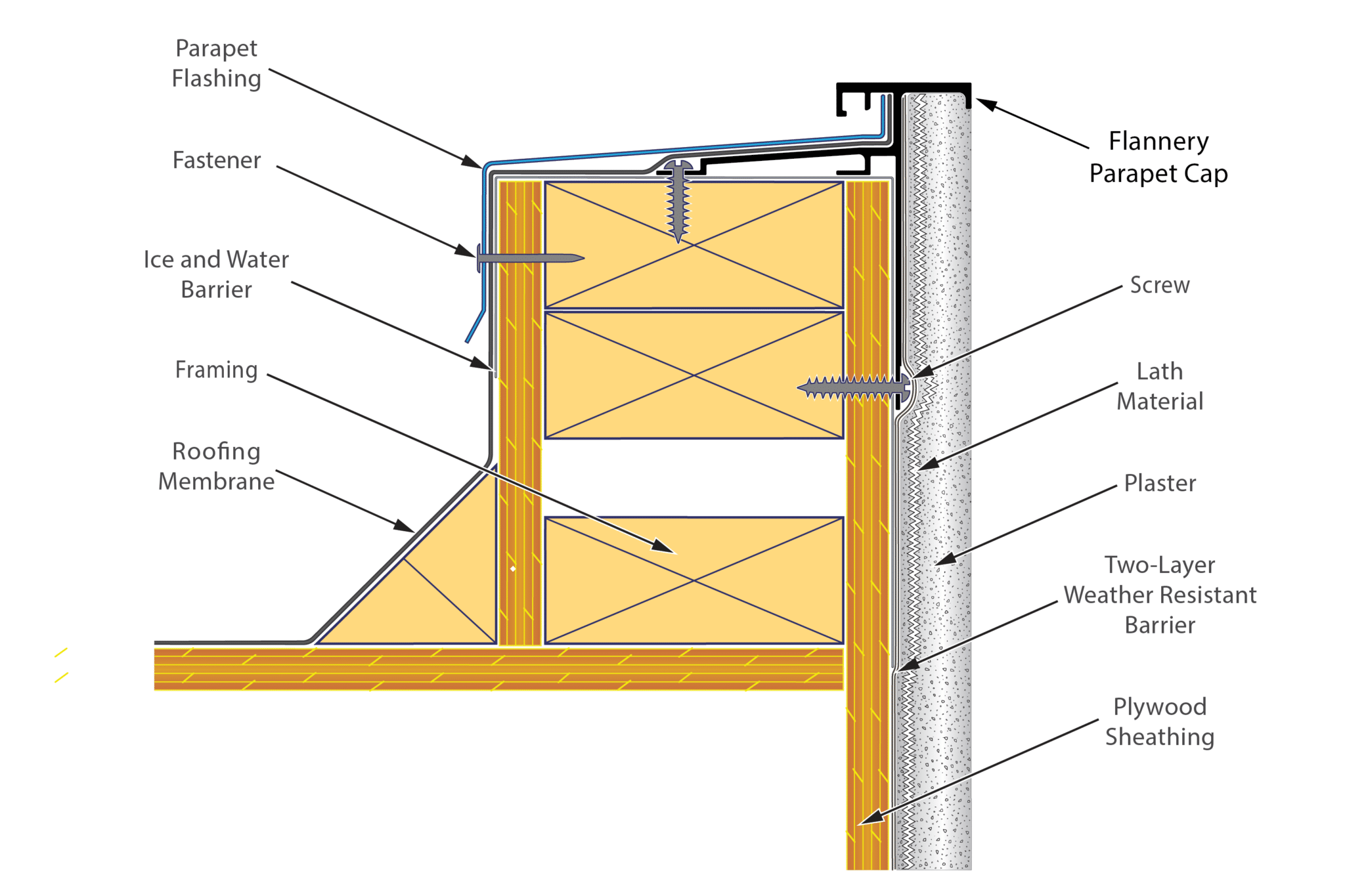

Install all Plaster Parapet Caps using full ten-foot lengths wherever possible. Attach the Parapet Caps over the weather resistant barrier to the framing with nails, screws or other approved fastening methods. Attachment flanges where stucco will be applied must be covered with lath. Fastener heads and butt joints must be sealed with sealant to prevent water intrusion. In addition, the roofing membrane must be installed over the horizontal flange of the parapet cap to prevent water intrusion on the roof side of the installation prior to the sheet metal flashing installation. Flannery recommends a carbide tip blade with lubricant be used when cutting any extruded aluminum trims.

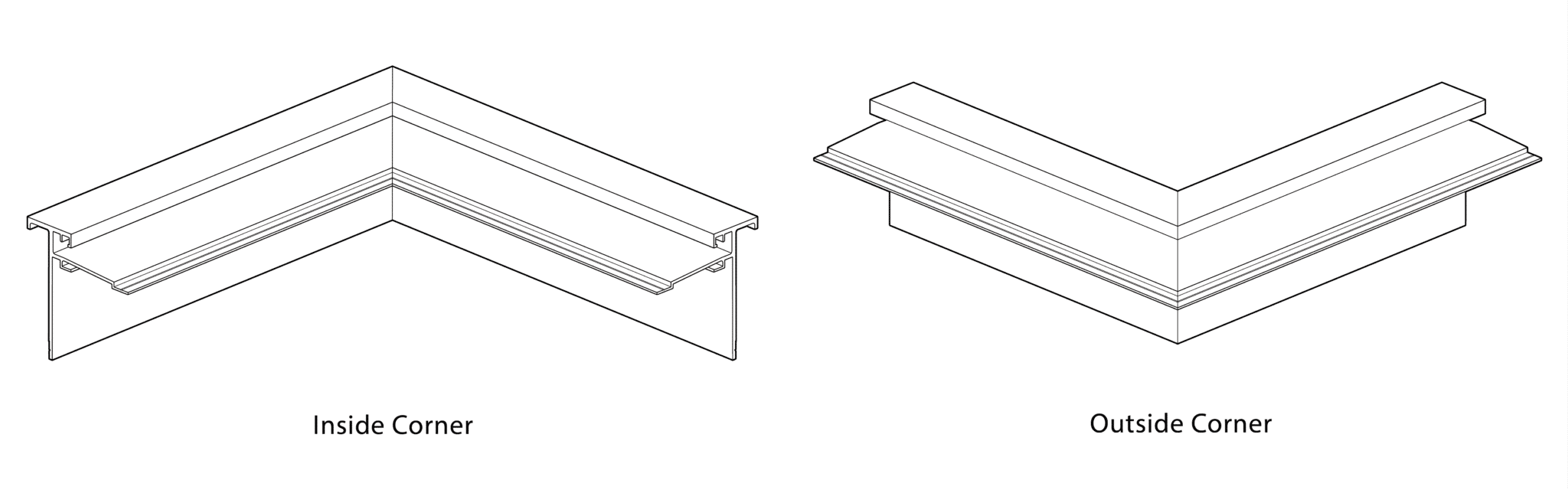

Flannery offers prefabricated Inside and Outside Corners for the Plaster Parapet Cap to ease the installation process in the field and to create the most aesthetically pleasing design. Factory fabricated corners are cut, mitered and then welded in Flannery’s facility with 6” legs (custom lengths also available) and can be installed on the corner of the building. The installer then runs the standard straight material length right up to the fabricated corner per the spec.