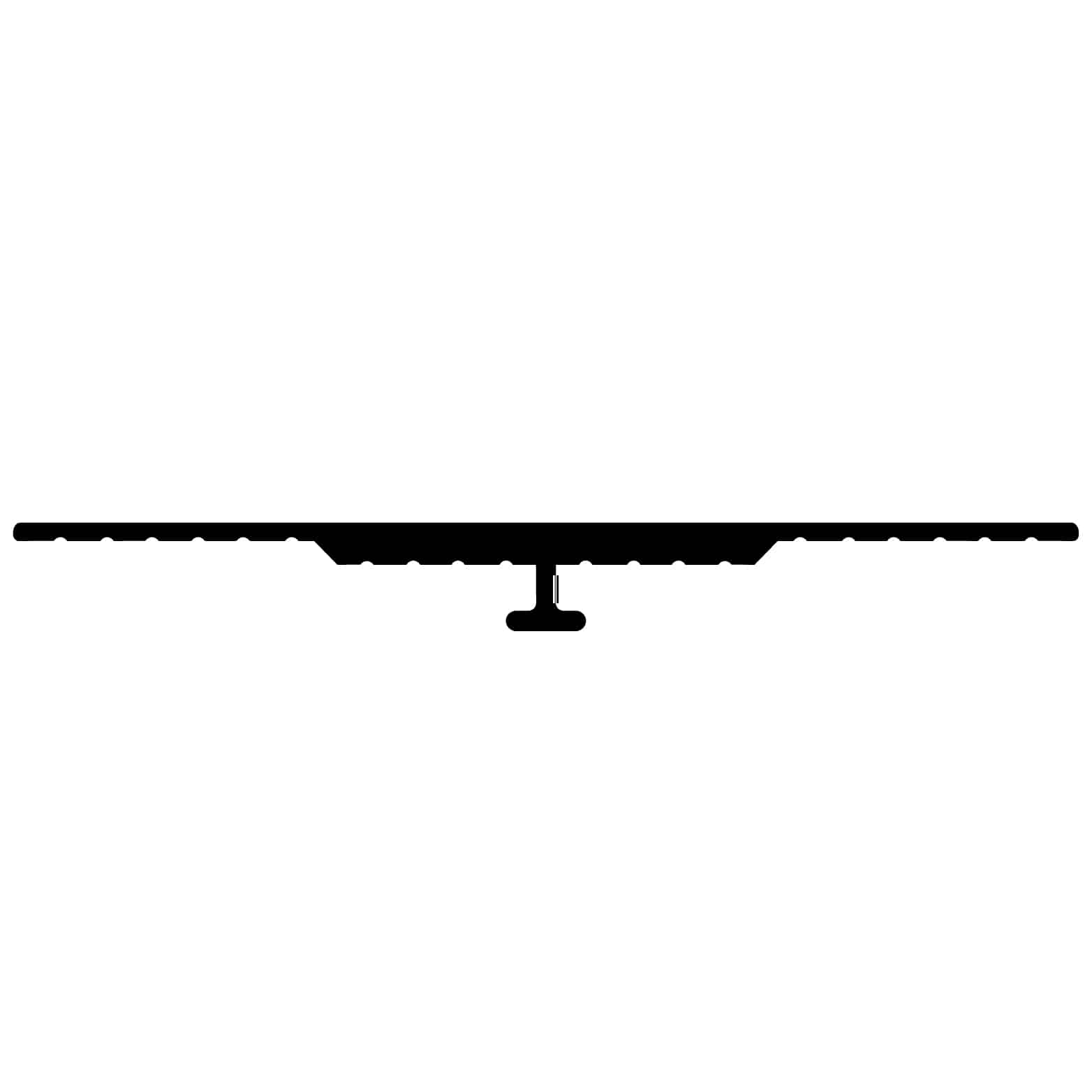

Wall Covering H-Mold

Trim Purpose

Specs, MSDS, and LEED Information for Flannery Trims & Products

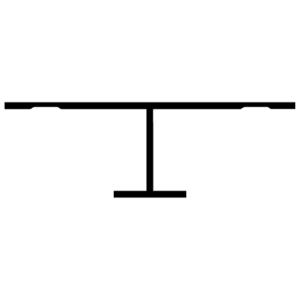

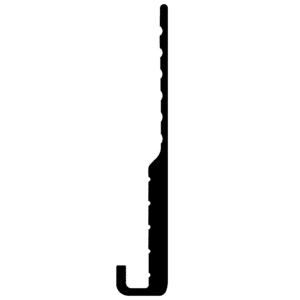

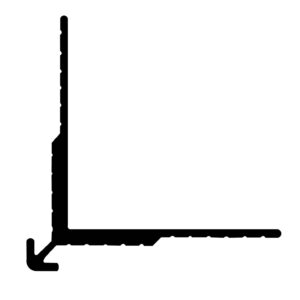

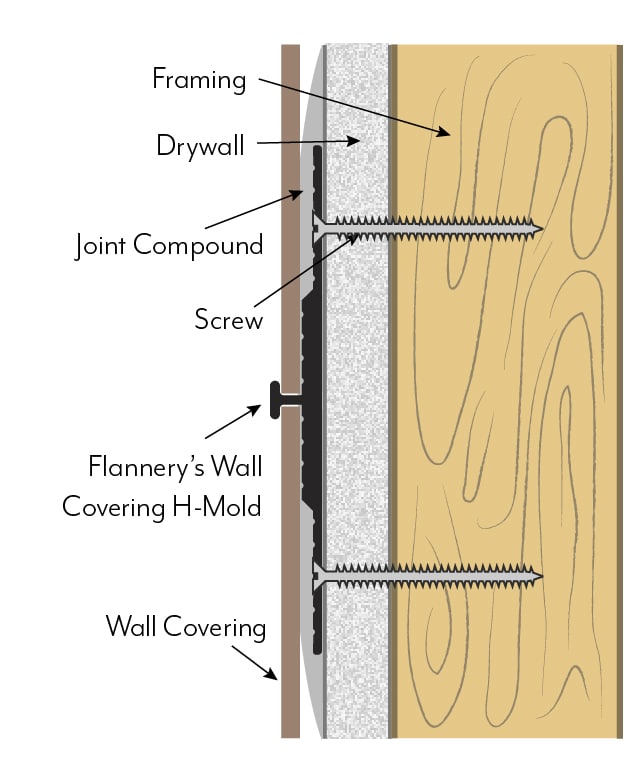

Flannery’s Wall Covering H-Mold (WCH 125-217) is a trim for FRP (Fiberglass Reinforced Plastic) panels or wall coverings and is to be installed over a new or existing gypsum board which creates a “flat-face” reveal between two adjoining panels. The H-Mold can be utilized to cover or conceal joints between FRP panels or wall coverings that need a clean joint and offer a put together look. The Wall Covering H-Mold has a tapeable flanges so that it can be finished to drywall cleanly and the wall covering material can be applied smoothly so the end result looks great. Want to learn more about wall coverings and the other wall covering trims we have to offer? Take a look at our article on our trim blog to learn more and see how wall coverings are a viable option for your next interior project!

Product Specifications

Flannery’s Wall Covering Trims are standard extruded aluminum alloy 6063 T5 and have a .050” nominal wall thickness. Our Wall Covering Trims are meant for FRP (Fiberglass Reinforced Plastic) panels or wall coverings. We have three new wall covering trims including our H-Mold. All of our Aluminum trims come in 10’ lengths (unless otherwise specified) and shall have a standard Mill Finish (for field priming & painting) or a Clear Anodized finish. Other factory finishes and custom paint orders, including Chem-film or Primer are available. You can view our factory finishes to see if we have what you are looking for or if you do not see the finish, you are looking for, chances are we can color-match it or we already have it! Flannery Trim wants to always make sure we can get you the right look and feel for your building project. *Scroll down to download the DWG and PDF files for the Wall Covering H-Mold!

install

Attach Flannery Wall Covering Trims over gypsum board (drywall) through the taping flange and into the framing with nails, screws or other approved fastening methods. All trims must be cut accurately and installed with tight neat joints. Drywall mud and tape is then applied to the mud flanges on the trims and then feathered, tapered and sanded for a smooth transition. FRP panel or wall covering material is then inserted into the trim and fastened to the gypsum board. Flannery recommends that a carbide tip blade along with blade lubricant be used when cutting aluminum trims.