3-Way Metal Corner Cap

Trim Purpose

Specs, MSDS, and LEED Information for Flannery Trims & Products

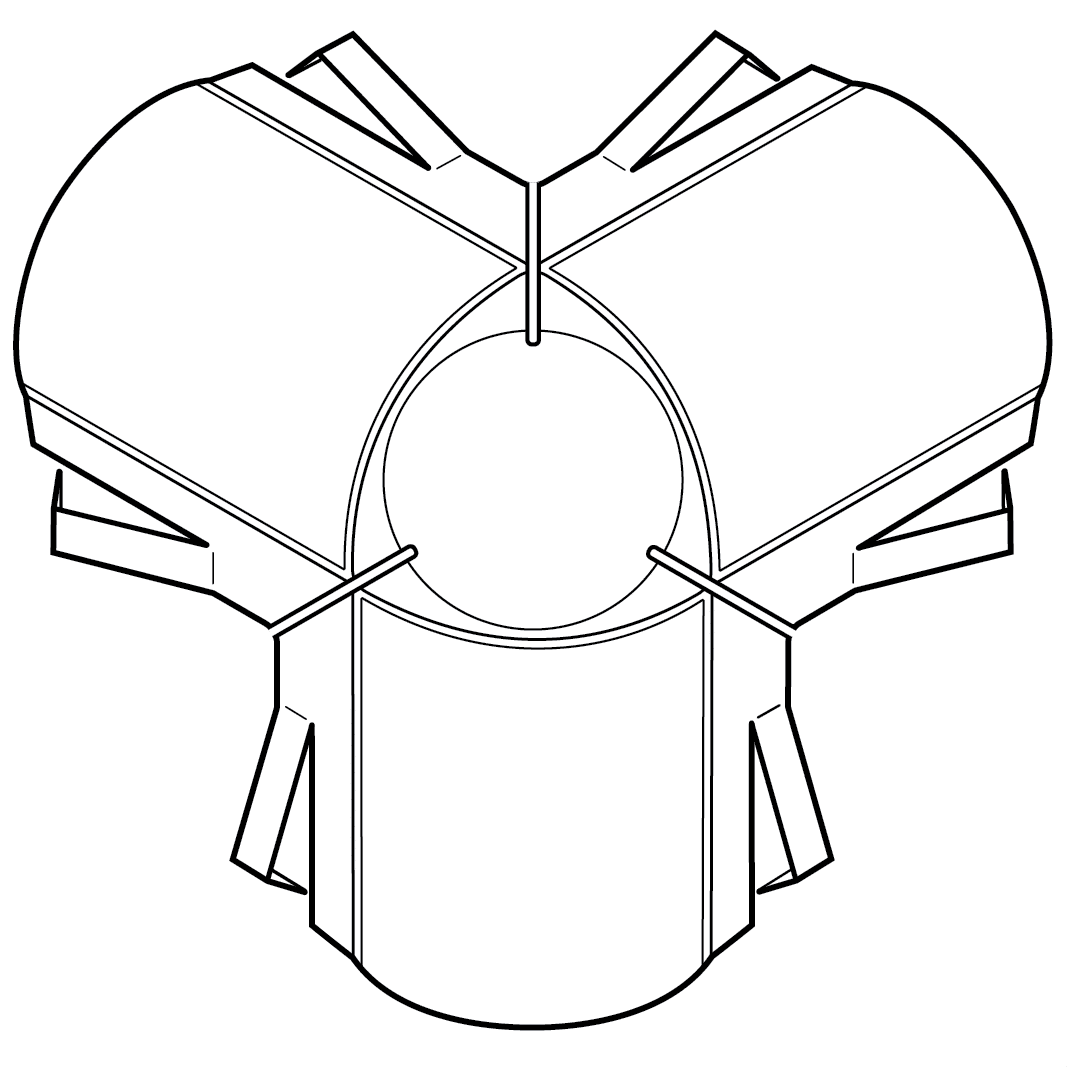

Flannery has been manufacturing Corner Caps for over 20 years and we have developed the 3-Way Locking Corner Cap (Patent #5,647,182) to be the last Corner Cap that you will ever want to use. This Bullnose Corner Cap allows three lines of bullnose to meet each other at one point.

3-Way Locking Corner Cap Specifications

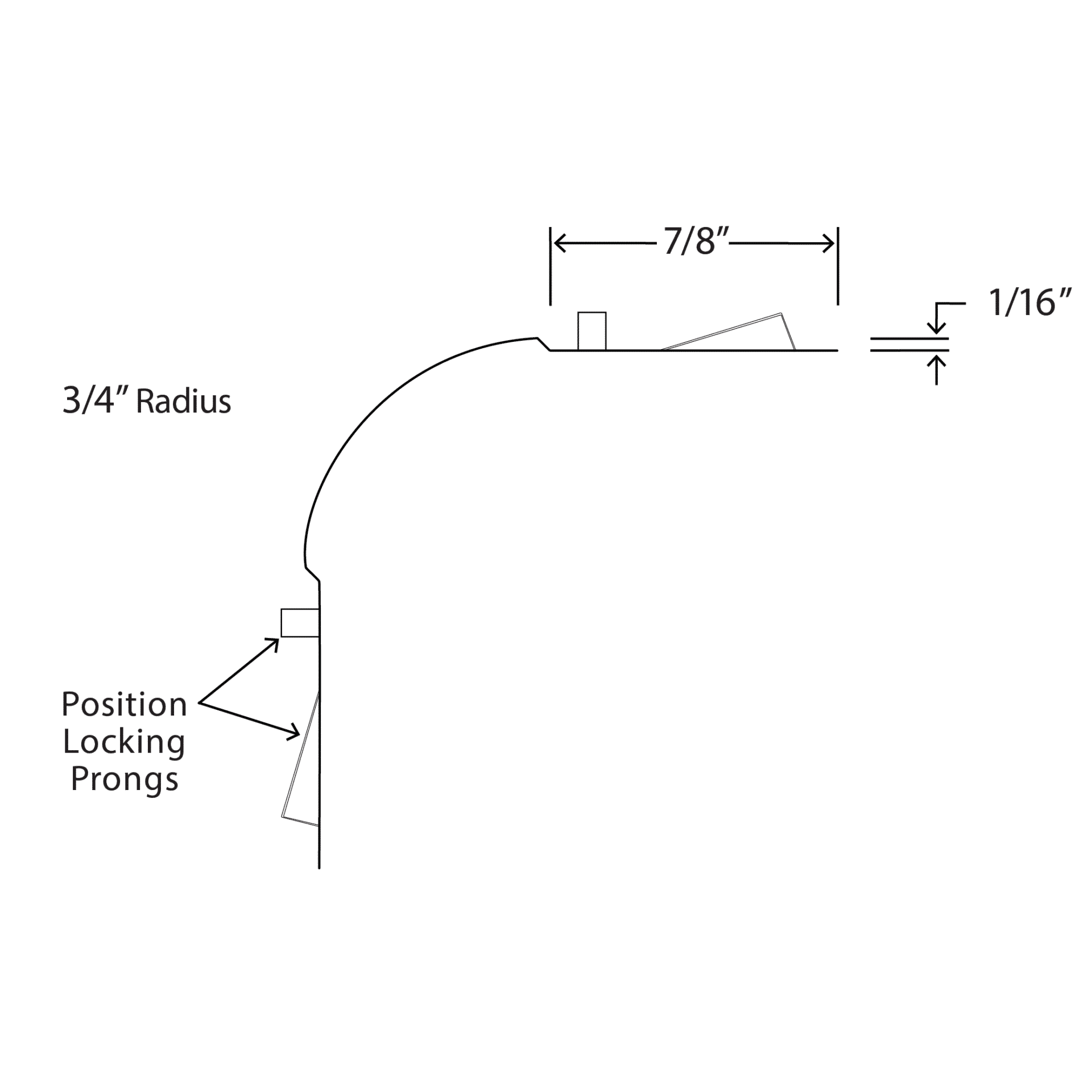

One of the main reasons to utilize Flannery’s 3-Way Locking Corner Cap is that it is a steel product which requires less mud during the taping process than ordinary vinyl corner caps. Vinyl corner caps are twice as thick as our metal corner cap and require 50% more taping compound to finish. The special beveled crown of our cap matches perfectly to most bullnose corners. Why waste money on attaching and taping your next corner cap, when you can use Flannery’s 3-Way Locking Corner Cap? Flannery steel trims are manufactured according to standard specifications for accessories of gypsum wallboard and gypsum veneer base (ASTM designation C 1047-85).

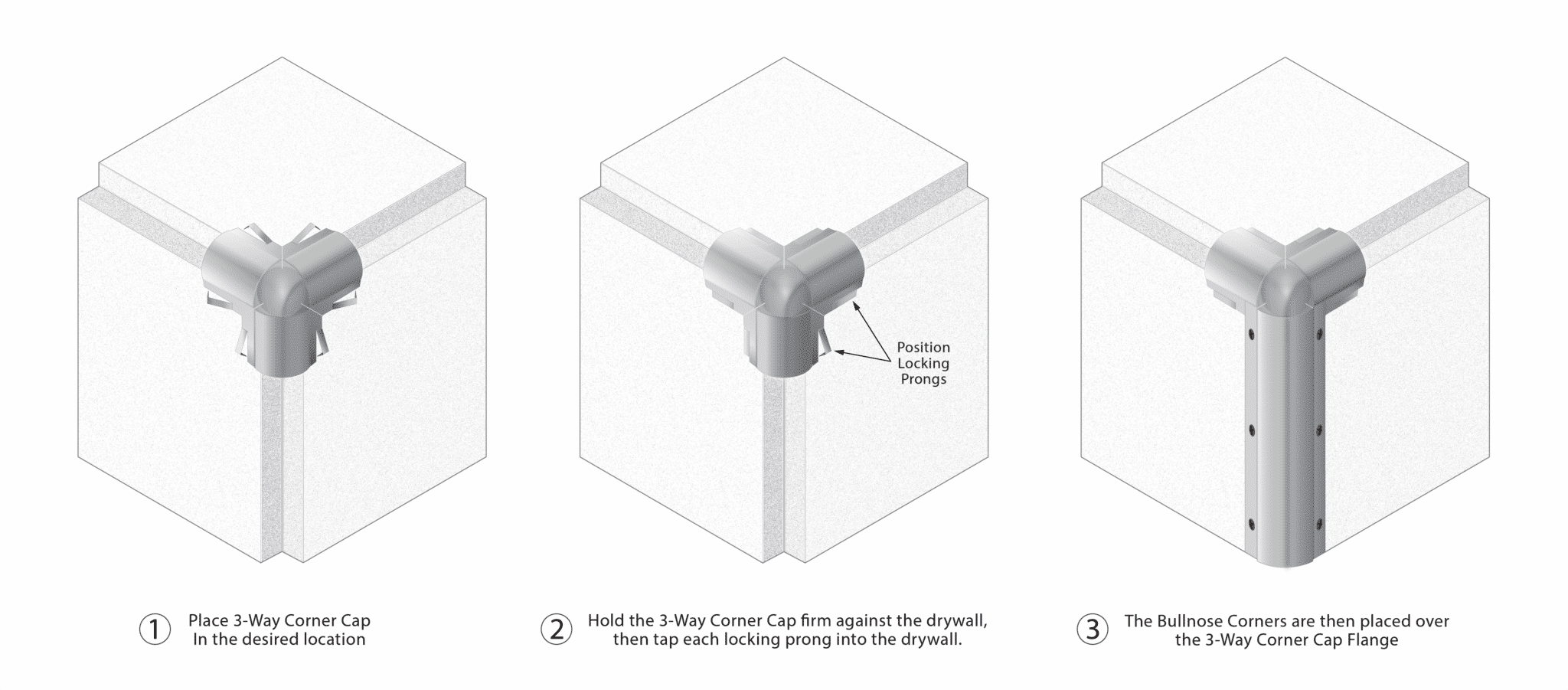

Installation Details for 3-Way Locking Corner Cap

Flannery’s 3-Way Locking Corner Cap is better than any other Cap because of the ease in which it can be installed. No staple, no nail, and no adhesive is required when installing our patented Self-Locking Corner Cap. Flannery’s Bullnose 3-Way Locking Corner Cap has six prongs (2 at each joint) that can be tapped into the drywall, thus holding it in place until your bullnose corners are installed over it.