Drywall T-Mold

Trim Purpose

Specs, MSDS, and LEED Information for Flannery Trims & Products

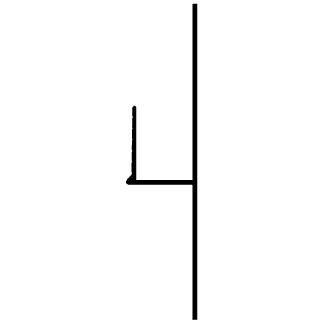

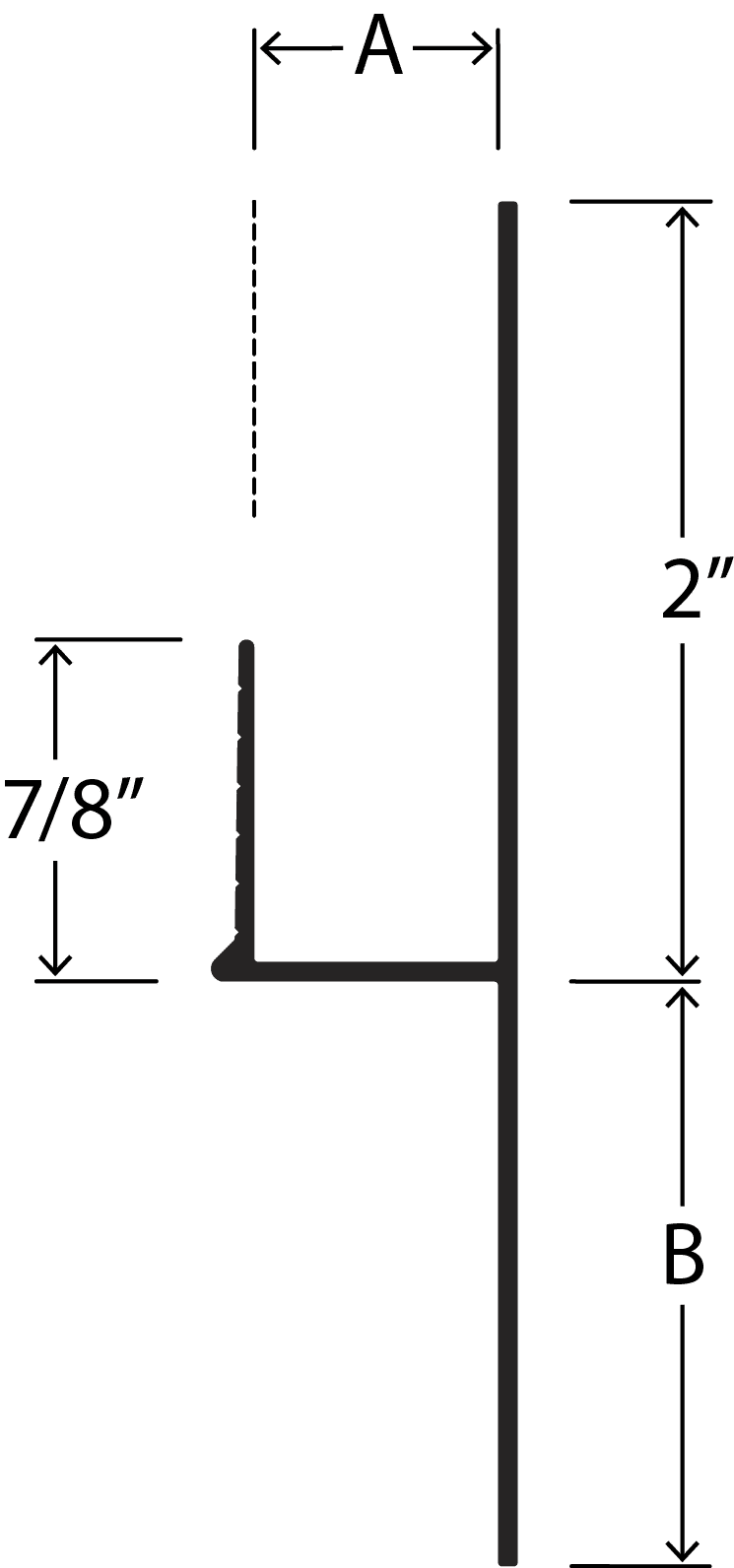

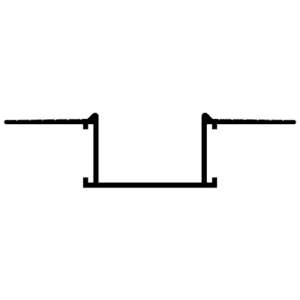

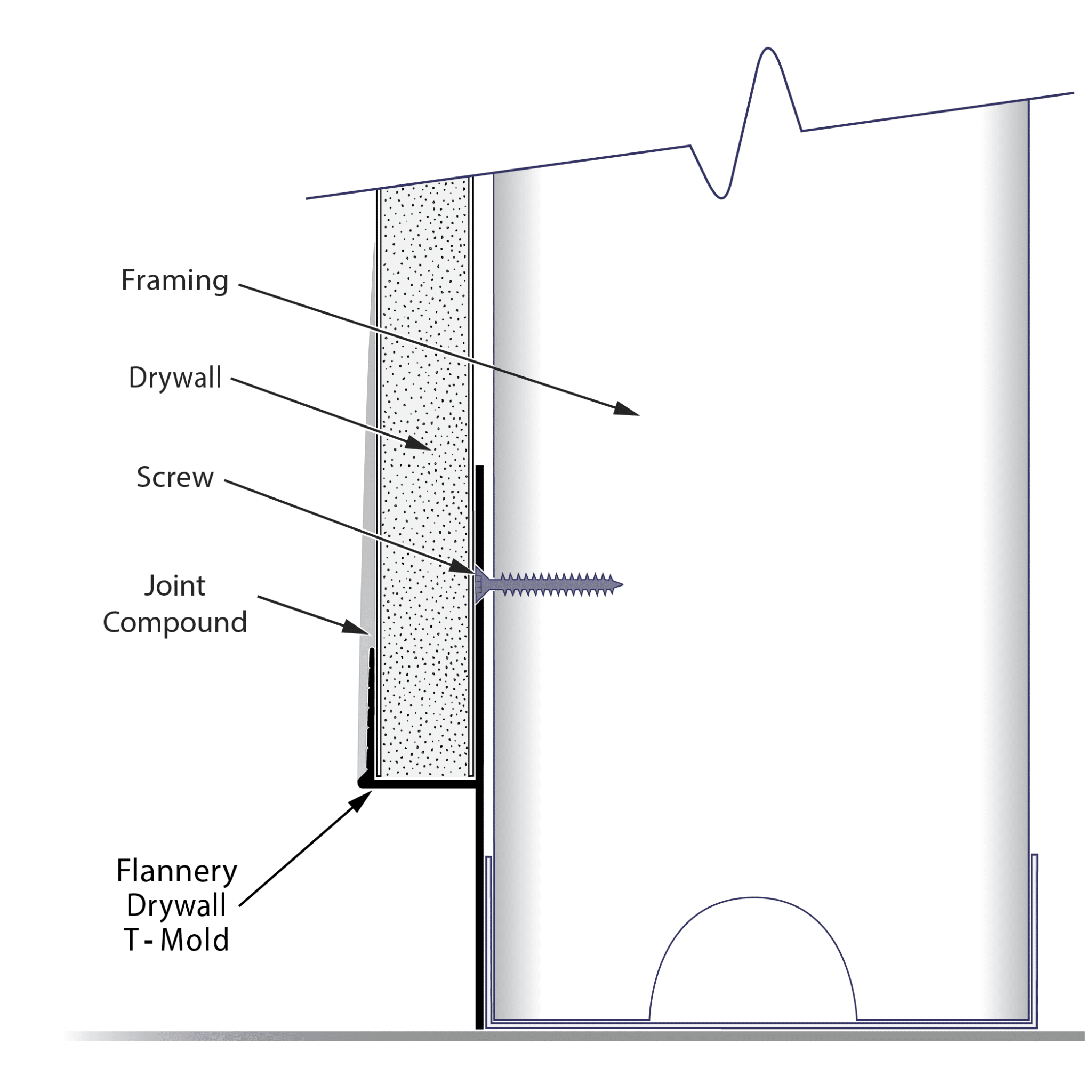

Flannery’s Drywall T-Mold is a base-of-wall trim that allows the installer to attach it to the framing prior to the installation of the gypsum board without losing the advantage of being able to tape and mud the trim to the drywall. Drywall T-Molds create the same aesthetic reveal between drywall and dissimilar materials that an Aluminum Drywall Shadow Mold would, with the advantage of setting the trim in place first.

Manufacturer Specs

Flannery’s Drywall T-Molds are standard extruded aluminum alloy 6063 T5 and are .050” thick. Aluminum trims come in 10′ lengths and shall have a standard Mill Finish for field priming and painting unless specified otherwise. Clear Anodized and Chem-film finishes, as well as other factory finishes and custom paint orders are available. You can view our factory finishes to see if we have what you are looking for or if you do not see the finish, you are looking for, chances are we can color-match it or we already have it! Flannery Trim wants to always make sure we can get you the right look and feel for your building project.

Installation Details

Attach Drywall T-Molds through the attachment flange to the framing with nails, screws, or other approved fastening methods. Insert drywall into the gap behind the tapeable flange and then apply compound joint and tape as needed. All drywall trims must be cut accurately and installed with tight, neat joints. Manufacturer recommends that a carbide tip blade along with blade lubricant be used when cutting any aluminum trim.

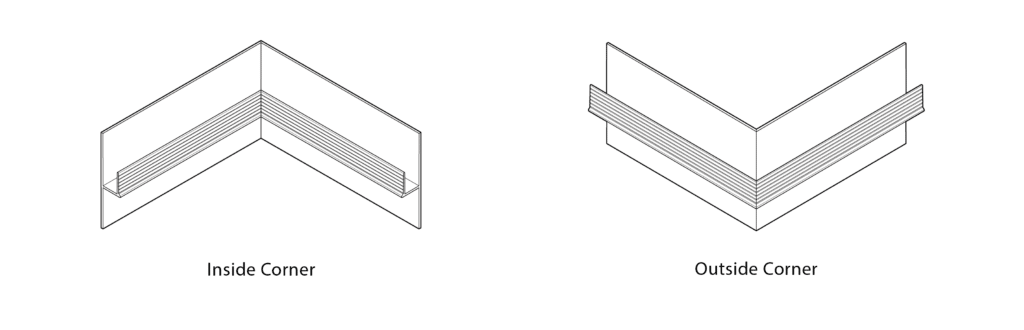

Flannery offers prefabricated corners for intricate wall designs that have trim transition from one wall to another. Prefabricated corners are mitered and then welded together at their attachment flanges. Factory welded corners come with 6” legs, however custom leg lengths can be ordered. Download the Corner and Intersections form or View All the Corner and Intersection Forms.