The Benefits of Exterior Wood Paneling Trim

Exterior wood paneling has become a top choice for multi-family housing (apartments, condos, etc.) and commercial retail and restaurant buildings. The increased popularity is due to the rise of a more natural-looking aesthetic. But what is great about many of the Panel options today is that you can get the same look of natural wood while still using sustainable materials like Composite (a material made with a mix of recycled materials like fibers and resins). In addition to Composite material, Aluminum siding has become a new popular material option (which Flannery has been using for our Extrusions for the last few decades).

Using Wood Paneling for the exterior of your building is a great way to make your building stand out from the norm. Most commercial and Multi-Family housing units opt for Stucco or Drywall options because of the costs. However, adding Wood Paneling to your building project can be so worth it in the long run for better curb appeal, and you often don’t have to refinish the building or paint it because the Wood Paneling options of today do not degrade or fade like natural wood. However, you still get a nice authentic wood look.

Curious about Flannery’s role in all this? We’ve meticulously crafted a range of Aluminum trims that not only enhance your panel system’s look but also offer functional benefits. Our trims serve as excellent transitions and corners for your chosen siding system. Among our most sought-after shapes are the J-Mold, Inside and Outside Corners, H-Mold, and Furring Strips.

At Flannery, we understand the importance of customization in your building projects. That’s why our Panel trims typically come in a Clear Anodized finish, with some shapes also stocked in our Black Anodized finish. But we don’t stop there. We can color-match the trim to your paneling and even add a wood grain texture to our trim for seamless integration. Call today to explore our wide range of finishing options for our panel trims and see how we can help you bring your design vision to life.

Considering Exterior Wood Paneling for your next project? It’s a smart choice that can be further elevated with Flannery’s Panel Trims. For more details on our Panel Trim extrusion options, keep reading below. And when you’re ready to take the next step, reach out to us for a personalized consultation. We’re here to help you make the most informed decision for your building project.

More Details on some of our Wood Panel Trims

|

|

|

|

||

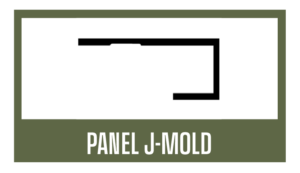

Panel J-Mold |

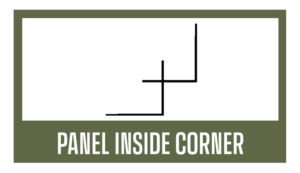

Panel Inside Corner |

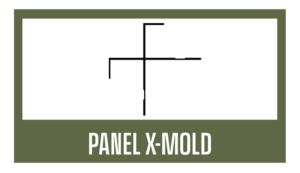

Panel X-Mold |

||

| A termination trim for siding that allows the siding to terminate against a dissimilar wall or material. By using the Siding J-Mold you can maintain a nice clean flow of the siding and avoid any rough edges from disrupting the aesthetics of the wall system. | Creates a sharp and crisp corner where siding is installed on walls that meet at a 90° inside corner joint. The Inside Corner trim creates a solid and clean corner for the siding system which would normally require the two pieces of siding to be laid together at an inside corner. | Creates a reveal at a 90° outside corner joint where siding is installed. The Siding X-Mold creates a solid and clean corner reveal for the siding system which would normally require the siding to be mitered and laid together at the edge. |

|

|

|

||

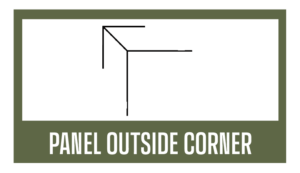

Panel Outside Corner |

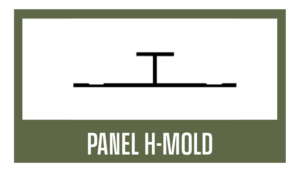

Panel H-Mold |

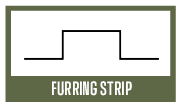

Furring Strip |

||

| Creates a sharp and crisp corner edge where siding is installed on walls that meet at a 90° outside corner joint. The Outside Corner trim creates a solid and clean corner for the siding system which would normally require the siding to be mitered and laid together at the edge. | A trim for siding that creates a “flat-face” reveal over two adjoining siding pieces. The Siding H-Mold is an important part of siding products that might require a relief to the expansion and contraction of the siding. | Designed to hold panels or composite siding away from the substrate in order to allow for the movement of air behind the panels. Since our furring strips are manufactured with aluminum, they will never rot or rust out from behind the wall system. |