Aluminum Drywall Shadow Mold

Trim Purpose

Specs, MSDS, and LEED Information for Flannery Trims & Products

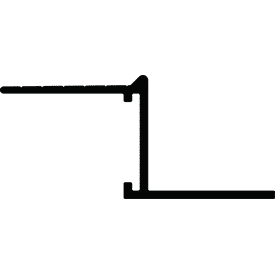

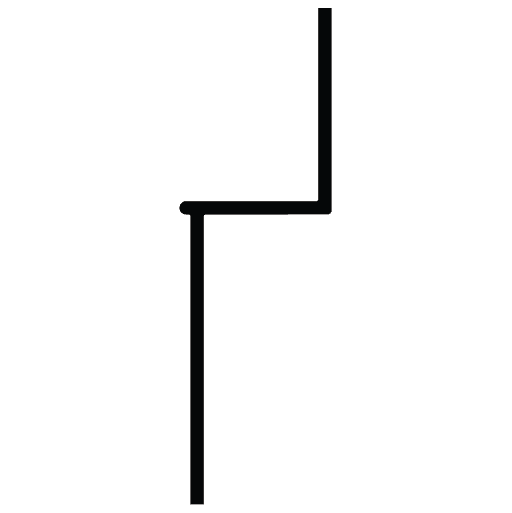

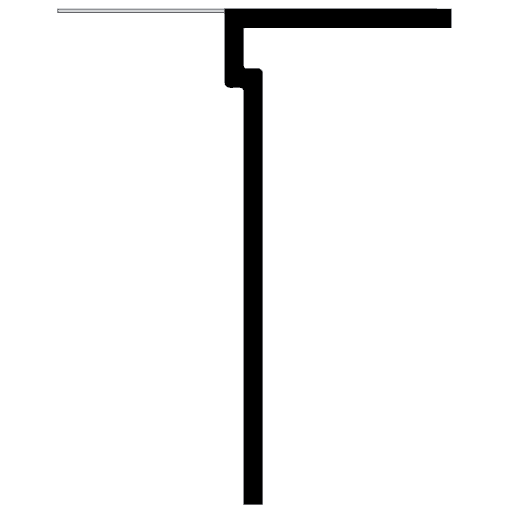

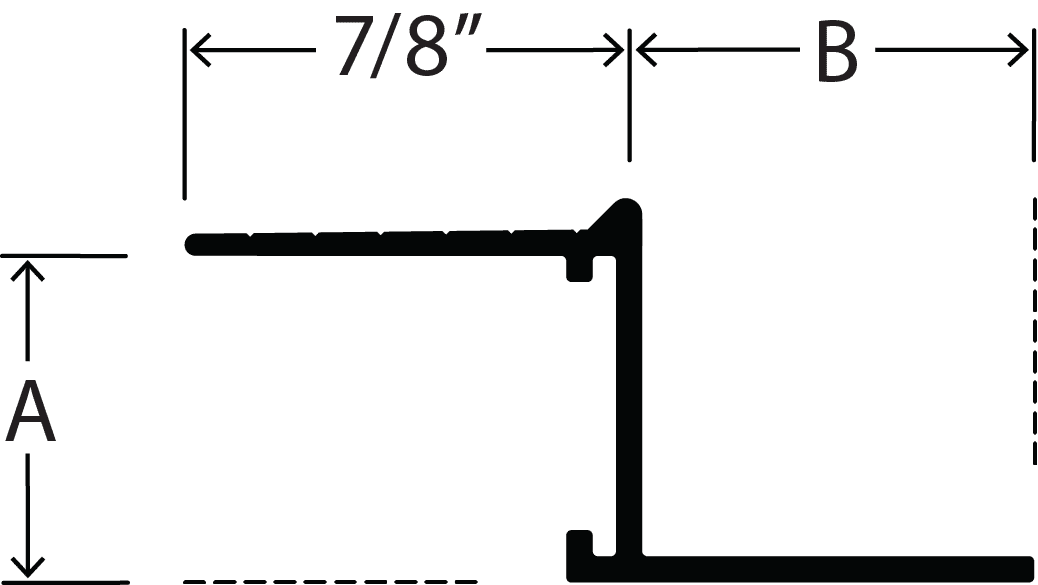

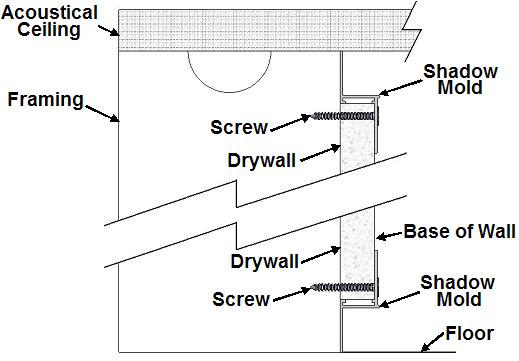

Flannery’s Aluminum Drywall Shadow Molds (or Z-Metals) create an aesthetic reveal between drywall and dissimilar materials including door and window frames, ceilings, and floors. Shadow Molds can be used to terminate drywall at the top or bottom of vertical walls and act as a reveal base. Shadow Molding can also be inserted into Kerf slots along door and window frames. Flannery offers many of its Drywall Shadow Molds with Aluminum Alignment Splices to ease the installation process and create crisp and clean butt joints and lines.

Product Description

Aluminum Drywall Shadow Molds are standard extruded aluminum alloy 6063 T5 and are .050” thick. Flannery’s Shadow Moldings come in 10′ lengths and shall have a standard Mill Finish for field priming and painting unless specified otherwise. Clear Anodized and Chem-film finishes, as well as other factory finishes and custom paint orders are available. Click here to view all of our factory finishes. You can view our factory finishes to see if we have what you are looking for or if you do not see the finish, you are looking for, chances are we can color-match it or we already have it! Flannery Trim wants to always make sure we can get you the right look and feel for your building project.

Shadow Mold is also known as: Z-Shadow and Z-Metal in the industry.

*Indicates Modified Part

Attach Aluminum Drywall Shadow Molds through the taping flange to the drywall and framing with nails, screws, or other approved fastening methods. All reveals must be cut accurately and installed with tight, neat joints. Manufacturer recommends that a carbide tip blade along with blade lubricant be used when cutting any aluminum trim. Flannery offers factory cutting and pre-fabricated intersections and corners for all drywall reveals, which can reduce labor costs and waste.

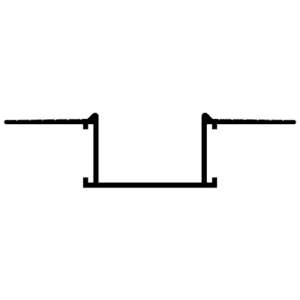

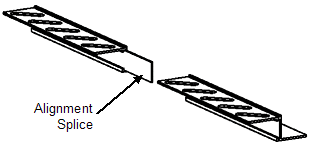

Channel Alignment Splices

Many of Flannery’s Aluminum Drywall Shadow Molds come with Aluminum Alignment Splices to ease the installation process and create crisp and clean butt joints and lines.

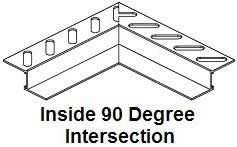

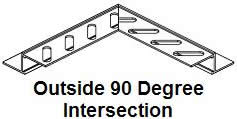

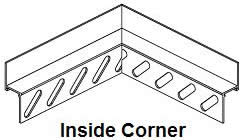

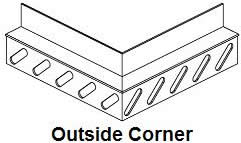

Flannery offers pre-fabricated intersections and corners for intricate building designs that utilize intersecting lines and bands on exterior or interior walls. These junctions can be produced in the field using Alignment Splices or can be ordered from the factory as prefabricated welded units to ease installation. Prefabricated intersections and corners are mitered and then welded at the nailing flanges. Factory welded intersections and corners come with 6” legs, however custom leg lengths can be ordered. Download the Corner and Intersection Form or View All the Corner and Intersection forms.

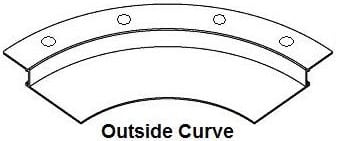

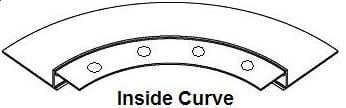

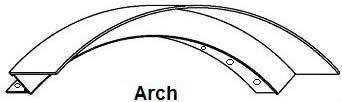

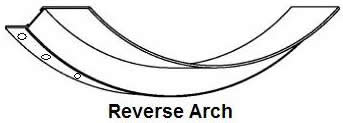

Flannery can radius Aluminum Drywall Shadow Molds when the trim runs along a “curved” or “radiused” plane. Radiused material is bent to a project’s dimensional requirements and is considered a custom product. Download the Radius Form or view all of our radius forms.