Standard Weep Screed

Trim Purpose

Specs, MSDS, and LEED Information for Flannery Trims & Products

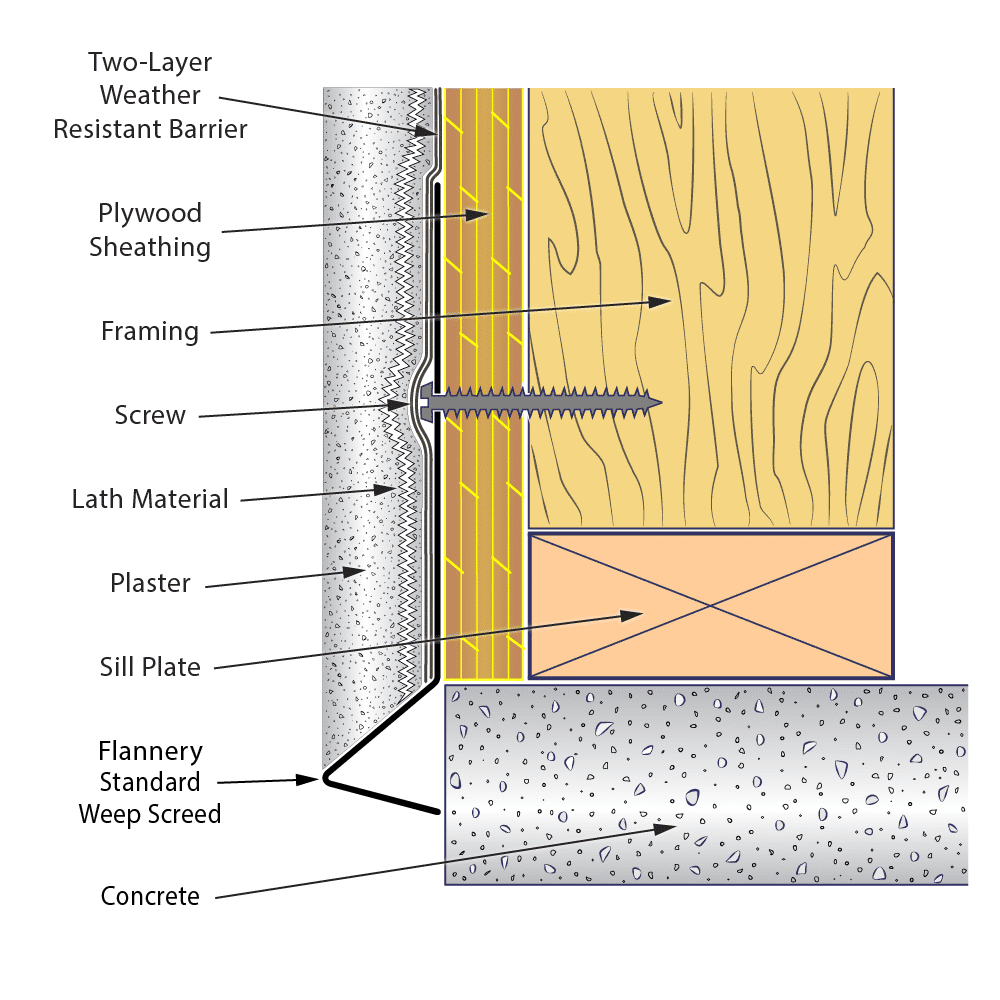

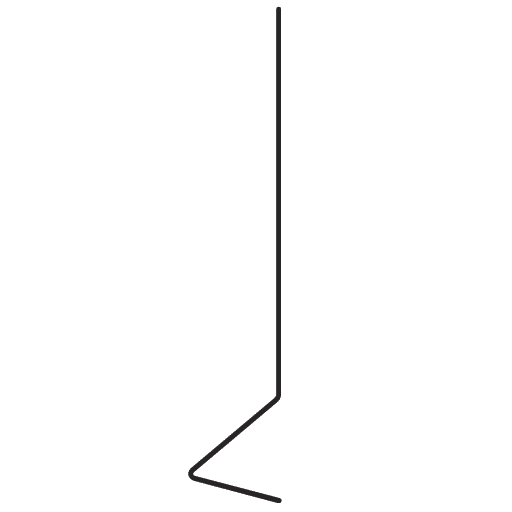

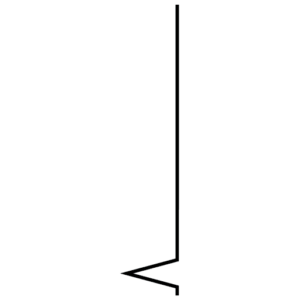

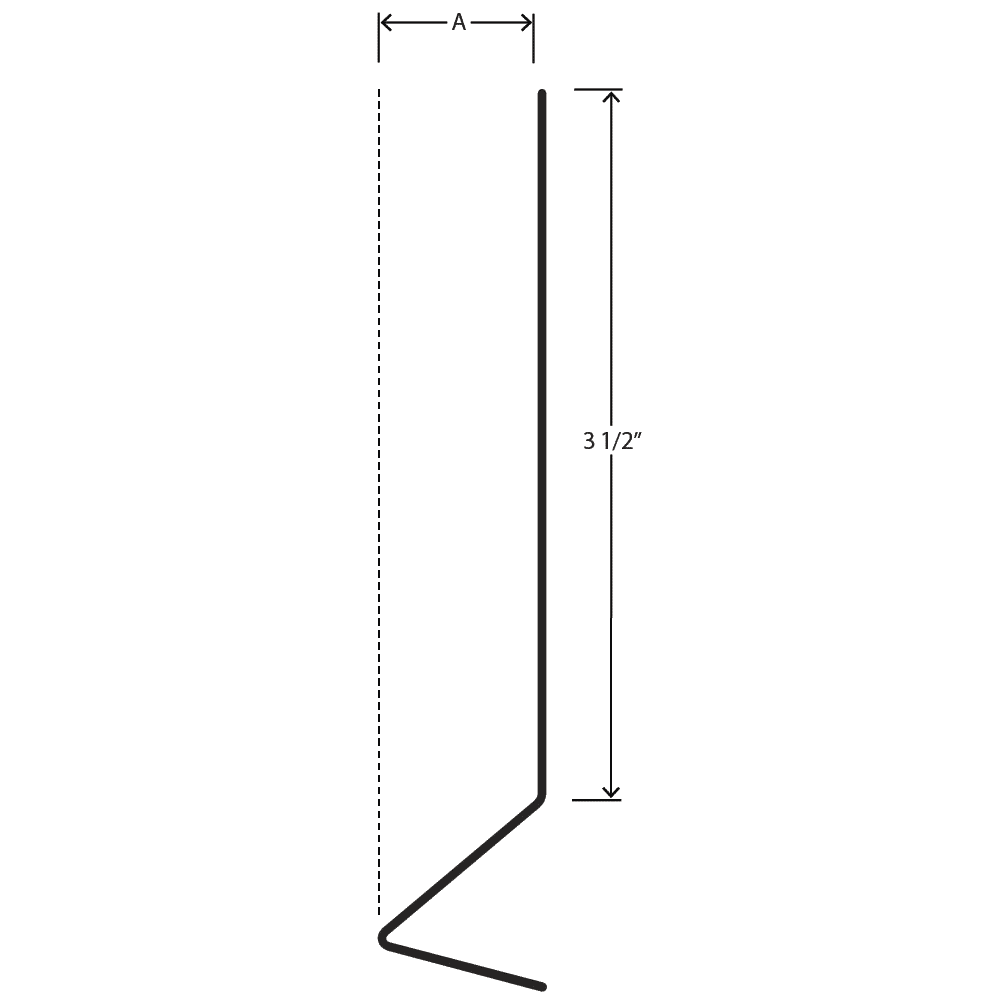

Flannery’s Standard Weep Screed (a.k.a. #7 Foundation Weep Screed) is a foundation weep screed with the benefit of a 3½” code leg. It performs as a stucco stop typically installed at the base of a stucco wall system. Its main purpose is to alleviate moisture from behind the plaster cement layer of a stucco wall system. Flannery’s Standard Weep Screed is a formed metal product and is available in Aluminum, Copper, Galvanized Steel, and Stainless Steel.

Manufacturer's Specifications

Flannery’s Standard Weep Screed is a brake formed metal product. Flannery’s Brake Formed products are available in a number of metals and finishes. Most can be specified in the following metals: .040” Thick Clear Anodized Aluminum; .040” Thick Mill Finish Aluminum; 26 ga. Copper; 26 ga. Stainless Steel T-304 #2 “Mill Finish”; 26 ga. Stainless Steel T-304 #4 “Brushed” Finish; and 26 ga. Galvanized Steel. Brake Formed products come in 10’ lengths and can be ordered in custom sizes and paint finishes.

| Metals Available: | Metal Code |

| .040″ Clear Anodized Aluminum | CA |

| .040″ Mill Finish Aluminum | AL |

| 16 oz. Copper | CU |

| 26 ga. Galvanized Steel | GS |

| 26 ga. Stainless Steel Mill | SS |

| 26 ga. Brushed Stainless Steel | BS |

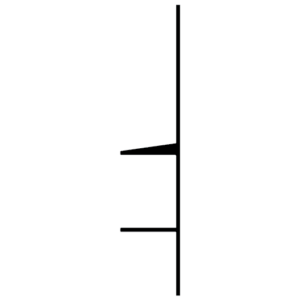

| Part No. | “A” Width | Available Metals | Stock Item |

| SWS 50 | 1/2″ | All | No |

| SWS 75 | 3/4″ | All | No |

| SWS 875 | 7/8″ | All | No |

| SWS 100 | 1″ | All | No |

| SWS 1250 | 1-1/4″ | All | No |

| SWS 150 | 1-1/2″ | All | No |

| SWS 1750 | 1-3/4″ | All | No |

| SWS 200 | 2″ | All | No |

| Custom Sizes Available |

Attach Weep Screeds to the framing with nails, screws, or other approved fastening methods. Attach the bottom edge of the Weep Screed no less than 1″ below the joint formed by the foundation and framing. The nose of the screed must be placed no less than 4 inches above raw earth or 2 inches above paved surfaces. The weather resistant barrier (two layers of building paper required if plywood sheathing is used) and lath must entirely cover the vertical attachment flange and terminate at the top edge of the nose or ground flange (per ASTM C 1063-03, Sec. 7.11.5).