Weeping Expansion Reveal

Trim Purpose

Specs, MSDS, and LEED Information for Flannery Trims & Products

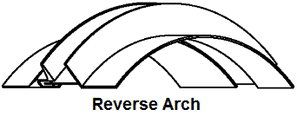

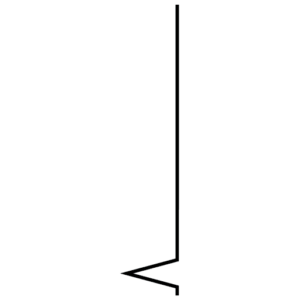

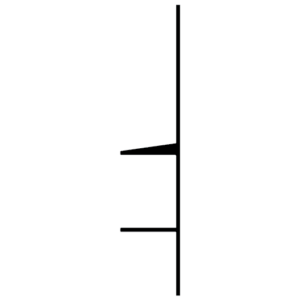

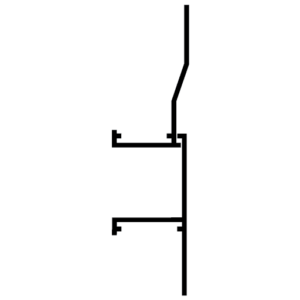

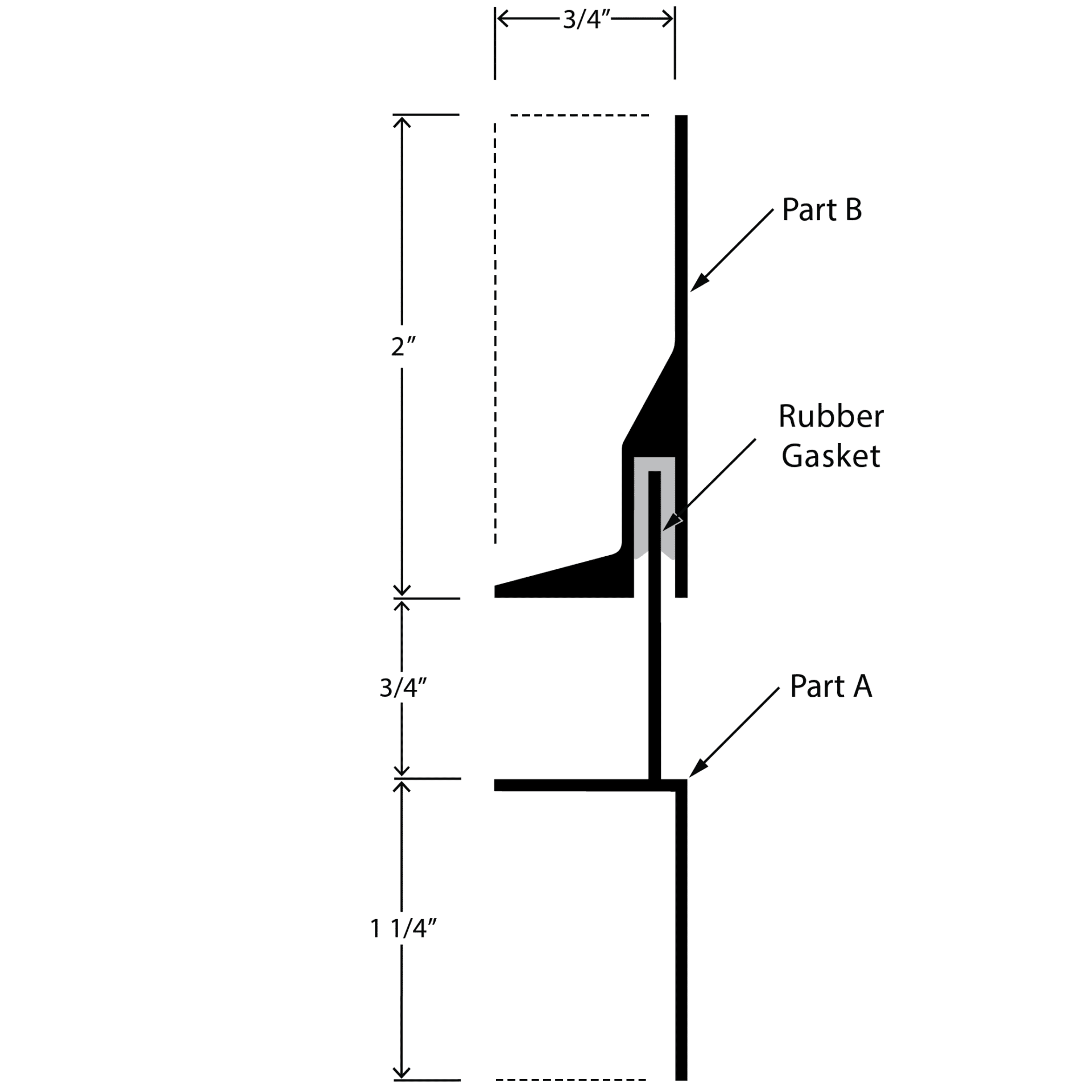

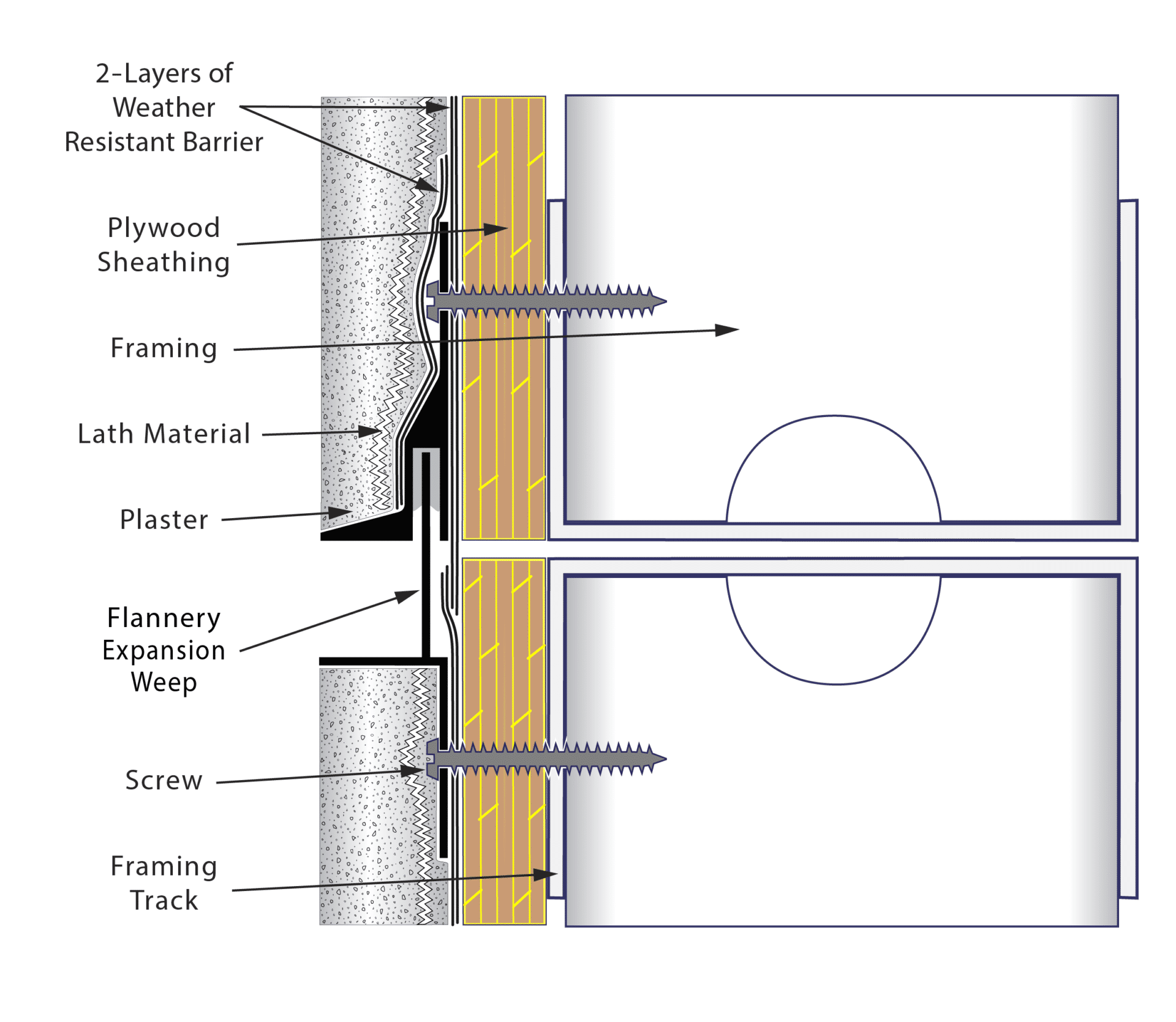

Flannery’s Expansion Weep acts as a plaster expansion joint designed to allow for the minor movement that may occur within an interior or exterior stucco finish. What makes the Expansion Weep unique is that it not only allows for the minor movement of the stucco finish, but it also acts as a “weeping” reveal. Flannery’s Expansion Weep assists in moving water out from behind the plaster layer of a stucco system. The upper horizontal projection (or “Ground Leg”) of the Expansion Weep is sloped to assist in draining moisture from the system similar to that of a foundation weep screed. The Expansion Weep comes with a rubber gasket to help join and seal Part A and Part B together. The Expansion Weep creates a ¾” aesthetic reveal and allows for a ¼” of movement.

Product Details

Flannery’s Plaster Channel Screeds are standard extruded aluminum alloy 6063 T5 and have a .050” nominal wall thickness. Aluminum Plaster trims come in 10′ lengths and shall have a standard Clear Anodized Finish. Mill Finish (for field priming & painting), Chem-film finish, or other factory finishes, and custom paint orders are available. You can view our factory finishes to see if we have what you are looking for. If you do not see the finish, you are looking for, chances are we can color-match it or we already have it!

Patent #6,374,559 B1

| Part No. | “A” Depth | “B” Width | Stucco Thickness | Vinyl Connectors | Stock Item | Downloads |

|---|---|---|---|---|---|---|

| EXPW 75-75 | 3/4″ | 3/4″ | 7/8″ | Yes | Yes |

|

Install all Expansion Weeps over the weather resistant barrier (WRB) on vertical surfaces using ten-foot lengths wherever possible. Part A, Part B, and the rubber gasket shall be factory assembled with vinyl connectors to ease installation. Attach Part A and Part B of the Expansion Weep to the framing with nails, screws, or other approved fastening methods. The next horizontal layer of building paper (or WRB) should overlap the nailing flange of Part B. All reveals must be cut accurately and installed with tight, neat joints. All nailing flanges must be covered with lath and all butt joints must be sealed. Manufacturer recommends that a carbide tip blade along with lubricant be used when cutting any aluminum trims. PLEASE NOTE: Attaching both Part A and Part B of the Expansion Weep to the same framing member or substrate will reduce or eliminate its expansion capabilities.

Patent #6,374,559 B1

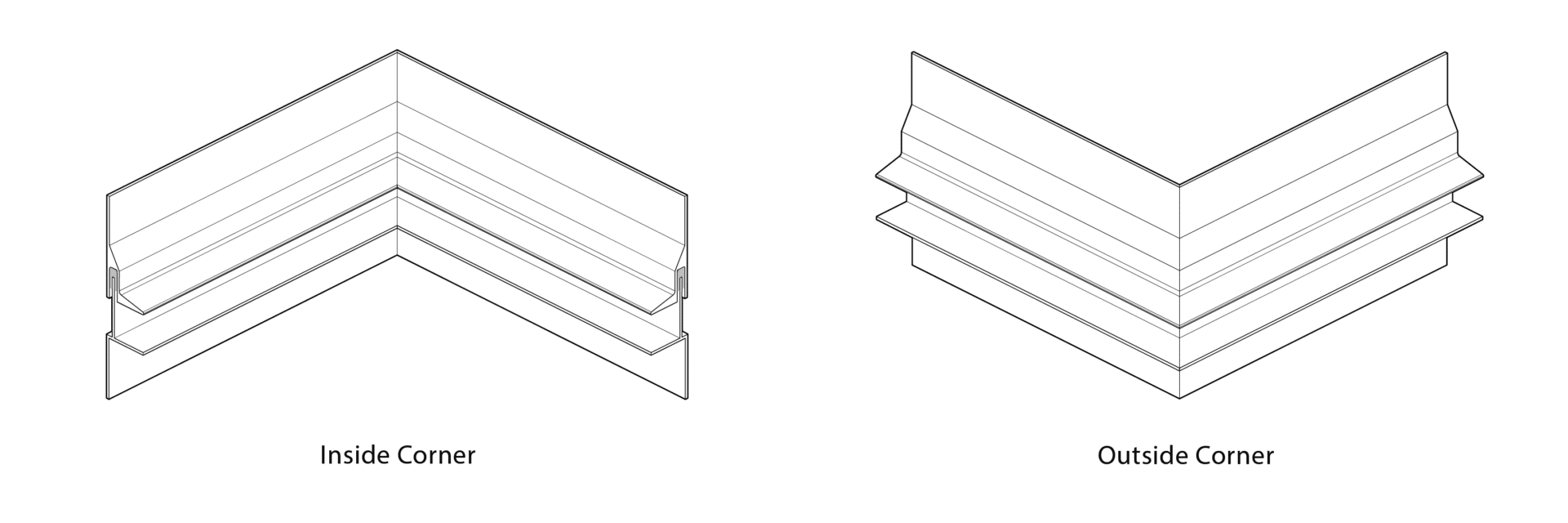

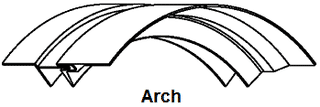

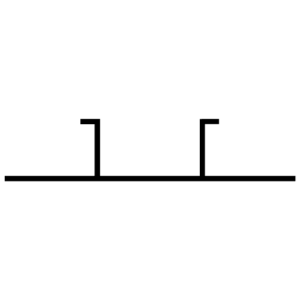

Flannery offers prefabricated corners for intricate building designs that utilize intersecting lines and bands on exterior walls. Prefabricated corners are mitered and then welded together at their attachment flanges, then vinyl tape is applied to the back of the reveal to prevent water intrusion. Factory welded corners come with 6” legs, however custom leg lengths can be ordered.